Cut-off Grade Optimisation

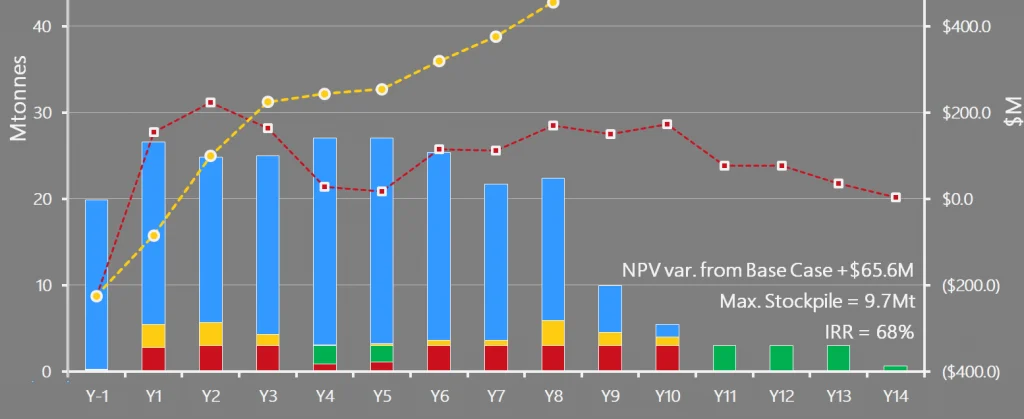

One of the key areas where a mining engineer can demonstrably add value to a mining project is in optimisation of the mill cut-off grade. The benefit to Net Present Value of determining an appropriate elevated cut-off grade strategy cannot be underestimated. It is not unusual to generate a value-add of greater than 10% by bringing higher grade ore forward and / or deferring feeding low grade material.

Orelogy have a unique combination of experience and toolsets in the area of cut-off grade evaluation. We have a proven track record in adding value to mining projects through a focused heuristic approach that optimises both cut-off grade policy and extraction sequence over time. This includes complex operations with multiple processing streams and complex stockpiling regimes.

Background – Maptek Evolution

In 2008, orelogy began development of a proprietary open pit scheduling tool called Evolution. Evolution was developed from a clean sheet and based on applying two fundamental approaches:

- Innovative heuristic algorithms – allowing multiple conflicting objectives to be dynamically optimised at the same time and;

- Leading edge computing frameworks – allowing the latest in high speed, cloud based computational power to be fully exploited

Evolution Strategy is the cut-off grade optimisation tool within the Evolution suite, and provides an unique capability to balance the key cut-off constraints, referred to as the “three M’s”:

- Mining

- Milling

- Market

Evolution Strategy can quickly and efficiently develop a strategic Life of Mine cut-off grade strategy for any grade targeted open pit mining project to any level of detail, from simple annual constraints, to flexing the mining cut-off by location and material type over time to truly maximise NPV.

In 2014 Maptek, a world leading mining software provider, acquired Evolution from Orelogy. Orelogy remain the power user of the software tool globally and have an unrivalled experience in its practical application.

Traditionally, cut-off grade optimisation has been considered a “high end” evaluation, usually requiring considerable time and cost to undertake and not always generating a practical outcome. Orelogy’s capability and experience in the use of the Evolution tool means that this process is no longer a preserve of Tier 1 mining groups.

Project Strategy Optimisation

Orelogy’s view is that open pit optimisation only provides part of the picture, the potential ultimate pit geometry. A practical mining schedule needs to be developed and assessed within these shells to determine which is the most profitable and robust shell to select for moving a project forward. Open pit optimisation tools are not proficient or transparent scheduling tools and therefore Orelogy’s approach is to undertake an assessment of a range of optimisation pit shells utilising the Evolution Strategy tool. This evaluation dovetails neatly with the traditional open pit optimisation component of any mining study and orelogy refers to this approach as Project Strategy Optimisation (PSO).

PSO not only optimises an elevated processing cut-off grade by mining location over time but also develops an optimal stage mining sequence and identifies opportunities to add value. As part of this assessment, throughput rates can be evaluated to determine the potential impact on stage development, vertical rates of advance and potential changes to equipment selection. PSO not only delivers a robust approach for selection of the final optimal shell to be used as the basis for pit designs, it also provides your project team with an early indication of:

- any value benefit from an optimised cut-off grade (or grade streaming) strategy and any associated stockpiling requirements.

- optimal staging geometries and sequence, and the associated strip ratio and mining rates and therefore equipment selection.

- ore presentation (grade/type) over time which allows an opportunity to evaluate and optimise process throughput and recoveries.

- what the robustness and sustainability of the final production schedule may be and any associated issues with bench turnover/mining rates.

Orelogy undertake PSO as an integral part of all their mining studies and this capability can be utilised by our clients at any time in their project life, from early Scale of Operation type assessments through the feasibility cycle to mature projects at any point in their operating life.